Pneumatic hoist is a kind of machinery that was invented later. After its appearance, it can make up for the problems of previous types of hoists. Its emergence is also a reflection of the continuous progress of science and technology. In the process of technological development, the production equipment needs to continuously meet people’s different needs. Only in this way can we promote the continuous development of the whole society and continuously improve the efficiency of work.

1/4T Air Hoist

1/2T Air Hoist

1T Air Hoist

Air hoists are all precision built chain type hoists which are designed with three rated loads, 1/4, 1/2 and 1TN. As per Customer’s request to produce up to 50tn loads.

Each model features a pendant throttle control, a swivel top mount hook and a swivel load chain hook with safety latch.

Air hoist is mainly used as a power source to drive the air motor to drive the internal mechanical parts to meet the working requirements of lifting heavy objects, so the air hoist is an environmentally friendly lifting tool.

The air hoist only needs the 0.5 ~ 0.6 Mpa ordinary compressed air.

It is small in size and operated easily and is only 1/3~1/8 of the weight of a motor hoist whose specification is same.

The air hoist cannot generate electric spark, so it completely solves the anti-explosive problem.

Basic Hoist Data

- Suspension: Hook

- Rated Loads: 1/4, 1/2, and 1Ton

- Control: Pendant Throttle

- Air Pressure Recommended: 90 psi

- Air Inlet Size: 3/8 NPTF

- Air Consumption: 48 SCFM at 90 psi

- Air Supply Hose: 1/2 I.D. min.

- Air Exhaust: 1/2 NPTF

- Net Weight (Basic Hoist): 36lbs

Specifications

| Type | Capacity (tons) | Pendant Throttle Control | Parts of Load Chain |

Lifting Speed Max (fpm) |

Lowering Speed Max (fpm) | Chain Length (In) | |

| Model No. | Net Wt.(lbs.) | ||||||

| Link Chain | 1/4 | 29SMS85,29SMS90 | 46 | 1 | 65 | 95 | 11’-5’’, 22’-7’’ |

| 1/2 | 29SMS86, 29SMS87 | 46 | 1 | 45 | 120 | 11’-5’’, 22’-7’’ | |

| 1 | 29SMS88, 29SMS89 | 59 | 2 | 23 | 60 | 22’-7’’, 44’-8’’ | |

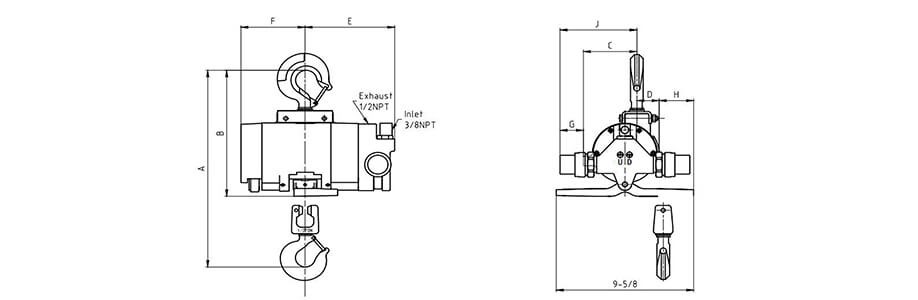

1/4 and 1/2TN Standard 1TN Standard

29SMS85, 29SMS90, 29SMS86, 29SMS87 29SMS88, 29SMS89

What are the advantages of air hoist?

In today’s society, lifting equipment already plays a very important role. Air hoist is an upgraded product of electric hoist, because it is compared with electric hoist and hand hoist.

But where is the superiority of the air hoist? When buying, what do you need to pay attention to? Let’s talk about it in detail.

First, the air hoist can operate continuously and at a high frequency. Because there are no motor parts, it will not cause the electronic and other components to become too hot due to excessively long working hours, which will cause failure. Devices like this also have a cooling effect during intake and exhaust.

Second, the lifting speed of the equipment can be adjusted and can be continuously variable. In this way, the speed of the pneumatic hoist can be adjusted, which can also be fine-tuned, which is very convenient.

Third, there will be no sparks during use. It can completely solve the explosion-proof of lifting equipment. Relying on compressed air and using it as a power source, it can be used in chemical and other places. It can work even in high temperature and high dust environment.

Fourth, because the structure of the pneumatic hoist is very compact, the number of accessories is small, and there are no electrical components. Therefore, it can work even in harsh environments.

Fifth, the pneumatic hoist is small in size, light in weight, and easy to install. Equipment of the same power, such as compared to electric hoists, is much smaller. It is very convenient for manual use and installation.

Sixth, the device can also prevent overload and self-locking. When lifting heavy objects, if the load capacity of the hoist is exceeded, it cannot be lifted.

Seventh, Higher security

The air hoist uses compressed air as the working medium. When working without sparks and electric shock, it has the advantages of fire resistance, explosion protection, humidity, high temperature and so on.

Eighth, Strong environmental adaptability

It can work safely under normal conditions under severe labor, dust, flammable, explosive, and humid environments.

Ninth, More convenient operation and maintenance

In terms of structure, the air motor does not need many parts to prevent electric sparks, making the structure simpler and more compact. Pipe and cable routing, using simple pipes instead of tedious and does not require professional operations. The maintenance of air hoist does not require professional technicians. Ordinary employees undergo simple training and maintenance.

Tenth, Longer life

Parts have high precision and long life. In addition, it can be used in the above normal operation at 60 ° C, so high temperature conditions are suitable for frequent work and long service life.

Classification basis of air hoist

Pneumatic hoist is the most ideal explosion-proof lifting equipment in the world. There are three types of commonly pneumatic hoists: vane, piston and cylinder.

Classification of pneumatic hoist

Chain pneumatic hoist, ultra-low pneumatic hoist (low net air hoist), mini pneumatic hoist, etc.

The pneumatic hoist can be combined with an explosion-proof trolley or a pneumatic trolley to form a mobile pneumatic lifting tool.

The cylinder type is also mainstream. The German JDN represent the vane type. Many companies produce the piston type. In comparison, the vane type will become the future development direction.

Composition of pneumatic hoist

Four parts make up the pneumatic hoist. They are the gas distribution system, the power system, the deceleration system and the hoisting system.

The chain hoist consists of three parts:

1. Lifting mechanism

2.Walking mechanism

3.Gas distribution system

The lifting mechanism includes an air motor, a planetary reducer, and a suspension assembly. And brakes, lifting chains, hook assemblies and main control valves. The lifting mechanism realizes the lifting and lowering of the lifting weight by controlling the main control valve. By opening and closing the brake, it achieves positioning braking for lifting and lowering. The chain hoist ensures the safety of lifting operations. We can use yale pneumatic hoist hoisting mechanism as a whole.

The pneumatic hoist walking mechanism adopts a pneumatic walking trolley. It contains active wheels, passive wheels, and wall panels. The main control valve controls the air motor and the planetary reducer to drive the active wheels to travel to achieve the horizontal movement of the lifting weight.

The air distribution system uses compressed air as the power source to control the lifting and walking of the pneumatic control hoist.

Daily maintenance of air hoist

During the use of any machinery, we must pay attention to its routine maintenance. Only in this way can it prolong its service life and improve its efficiency and safety. The same is true of the air hoist. Although it is not a very precise machine, it also needs daily maintenance. Only in this way can it make it better serve people’s production and improve its working efficiency in the process of lifting heavy objects.

First, the machine needs to be checked before using an air hoist. See if it meets the various needs of use.

Second, when not in use, pay special attention to the storage process. Do not store it in a damp place. It should be stored in a dry place.

Third, we must regularly clean and maintain the hoist. This is a measure that can improve its working efficiency, especially in the friction parts, pay more attention to its cleaning.

Fourth, because it uses a pneumatic method. It uses compressed air to provide power, so pay attention to some regulations on its compressed air device. Avoid causing problems during operation and reduce work efficiency.

Fifth, for the daily maintenance of the pneumatic hoist, special personnel need to be arranged to do this work. This can better ensure the effectiveness of maintenance. In addition, the personnel engaged in this work must have a certain degree of professionalism. This will ensure professionalism and increase the useful life of the machine.

Pneumatic hoist has been widely used in recent years. Because it has few restrictions, it can be used in industries with specific requirements. Pay attention to its daily maintenance to make it work better. And reduce the failure caused by machinery during work.

Precautions for air hoist

Electric hoist shall not lift and unload heavy objects by side. We cannot overload pneumatic hoists.

Avoid obstructions within walking distance of the operator. And on routes that the weight passes through.

Please fix the work piece firmly when using. Keep hands and rags away from rotating parts.

In the process of use, the operator should check the wire rope at any time. There is a disorderly buckle, knot, groove, wear and other phenomena. If there is, we should eliminate it in time.

In daily work, the limit device shall not be used artificially to stop the lifting of heavy objects or stop the operation of the equipment.

Manual control buttons up and down, left and right direction should be accurate and sensitive. Motor and reducer should have no abnormal sound

Special maintenance personnel should check the main performance and safety status of the electric hoist once a week and remove the fault in time.

After finishing the work, turn off the main power switch and cut off the main power.

Pneumatic hoist using gas dynamics, operation will not produce electric spark, safety and environmental protection hoisting tools.

Pneumatic hoist is through the compressed air to drive the air motor. To achieve the function of lifting heavy objects, explosion-proof is ideal.